Mechanical Rooms - Protection of Equipment and Personnel with Performance Coatings

The underbelly of many facilities large and small is traditionally filled with equipment critical to the building operation. In most cases, these rooms control comfort, air quality, elevator equipment, and backup power generation. This room is one of the larger investments in a building, caring for it is imperative, as downtime and replacement are costly.

Keeping your mechanical room organized, free from unnecessary clutter, and clean as far as dust, dirt, and debris are concerned, is not only important for equipment functions, but it is also safer for the personnel working around it.

When a mechanical room is clean and free of unnecessary clutter it not only becomes easier for technicians to address problems as they arise, it becomes easier to spot them earlier. When the status quo is one of organization and cleanliness, things such as breakdowns and leaks tend to jump out at the people responsible for managing the assets inside.

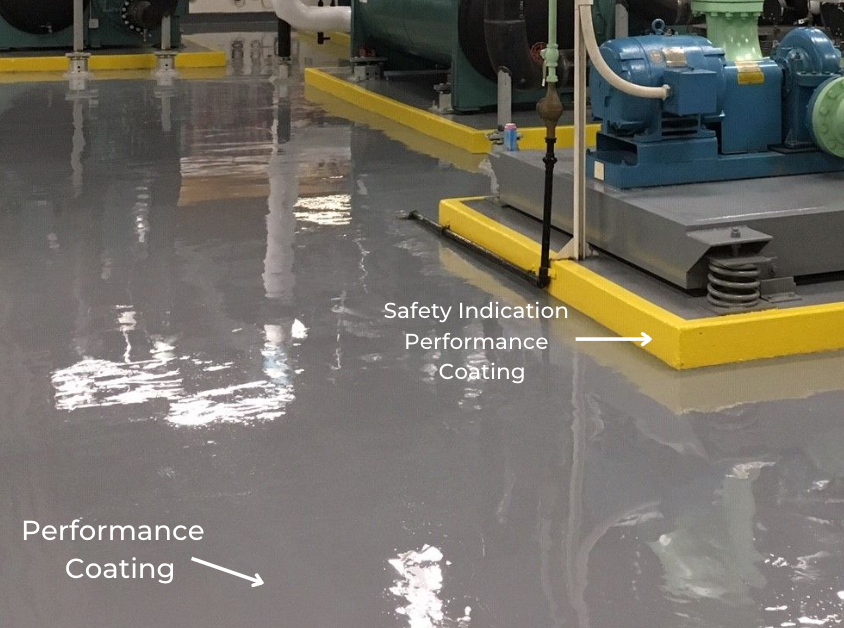

Safety identifiers. Painting equipment piping with colors that act as key indicators can allow technicians to identify needs more quickly. Safety colors and cleanable non-slip floor coatings will make for friendly spillage cleanup, protect the concrete underneath from harmful chemicals or contamination, and highlight potential tripping hazards for personnel working inside.

At a minimum, your mechanical or engine rooms should be neat and organized. If you would like for your mechanical room to become safer, easier to maintain, and better protected, reach out to Major Painting for your coatings needs.

About the author

Chase DeRousse is the Vice President of Painting at Major Painting and strives to deliver quality craftsmanship coupled with superior customer service, creating a unique and pleasant experience for all Major Painting customers, no matter the size of the project. Chase also holds an active Class A General Contracting License.

Chase has won multiple accolades recognizing his leadership and excellence in the painting industry including awards from the Painting Contractor Association (PCA), Business Owners and Managers Association (BOMA), and Institute of Real Estate Management (IREM).